Product overview

An electric damper is a valve that controls the airflow or air flow in a pipeline by driving the valve plate or valve core through an electric actuator.

Working principle

Electric actuator: The core component of an electric damper is the electric actuator, which is usually composed of an electric motor, a reducer, a travel switch, etc. When receiving the control signal, the motor starts and drives the reducer to operate, thereby driving the valve plate or valve core to move.

Transmission mechanism: The transmission mechanism converts the rotational motion of the electric actuator into linear or rotational motion of the valve plate or spool. Common transmission mechanisms include gear transmission, worm gear transmission, etc.

Valve body: The valve body is the main part of the electric air valve, which includes components such as valve plate or valve core, valve seat, sealing ring, etc. The movement of the valve plate or spool changes the opening of the valve, thereby controlling the flow rate of the medium.

Function description

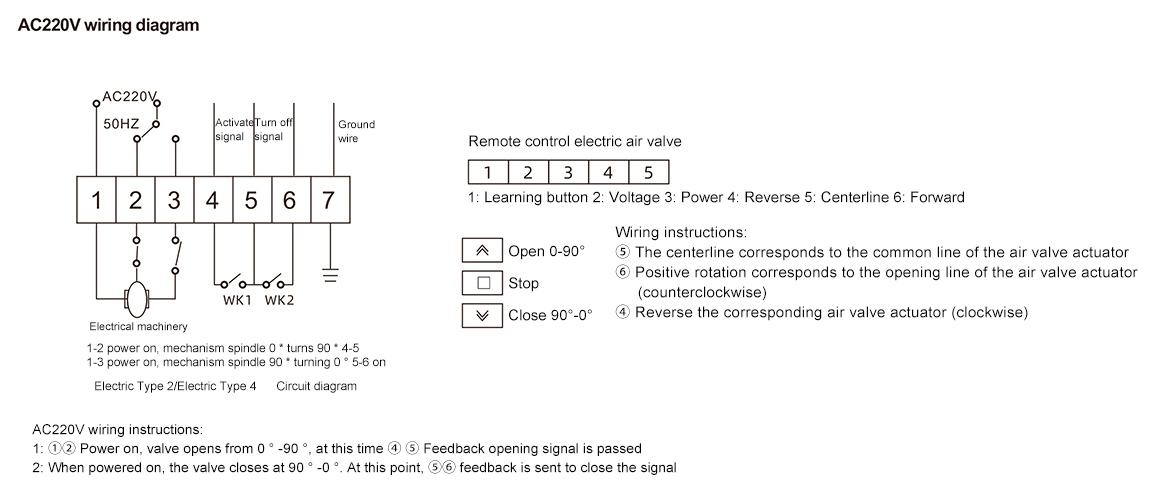

Remote control for opening and closing

● Feedback on/off signal (passive signal)

Effective distance within 10m

● Can be equipped with any actuator

● Easy to operate, wireless connection

● Voltage DC 24V, AC220V

Characteristics and advantages

High degree of automation: Electric air valves can be used in conjunction with automatic control systems to achieve remote control and automatic adjustment, improving the automation level of the system.

Easy to operate: The operation of the electric air valve is simple and convenient, and the valve can be opened and closed by simply controlling the signal, without the need for manual on-site operation.

Fast response speed: The electric air valve has a fast response speed and can quickly open and close the valve, meeting the demand for rapid adjustment of air volume.

Safe and reliable: The electric air valve is driven by an electric actuator, which poses no risk of electrical sparks and is suitable for occasions with high explosion-proof requirements. At the same time, the electric air valve has a complete limit device and fault alarm function to ensure the safe operation of the system.

Strong adaptability: The electric air valve has a compact structure, light weight, easy installation, and can adapt to harsh environments such as high temperature, humidity, and dust.

Structure and type

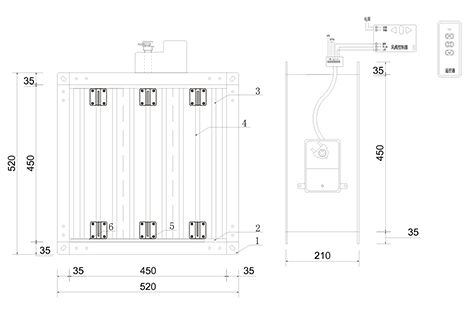

Structure: The structural design of electric air valves is diverse, but usually includes electric actuators, transmission mechanisms, valve bodies, and other parts. Among them, the valve body can adopt a new structural form of welding a midline disc plate and a short structural steel plate to improve the sealing performance and flow characteristics of the valve.

Type: According to different usage scenarios and functions, electric air valves can be divided into various types, such as regulating electric air valves, cut-off electric air valves, etc. Adjustable electric air valves can receive signals from the system and adjust the valve opening according to the magnitude of the signal, thereby controlling the flow rate of the medium. Cut off electric air valves are mainly used in situations where the flow of the medium needs to be completely cut off.

Application scenarios

Electric air valves are used in situations where air volume or airflow direction needs to be adjusted, especially in industrial environments that require high automation, fast response speed, and high safety and reliability requirements. For example:

Air conditioning system: Electric dampers are used in air conditioning systems to regulate parameters such as fresh air intake and return air volume, ensuring the freshness and comfort of indoor air.

Ventilation system: In ventilation systems of large commercial buildings, industrial plants, and other places, electric dampers are used to control the air output of fans, achieving indoor air circulation and renewal.

Environmental protection engineering: In ventilation and environmental protection engineering in industries such as hardware, chemical, building materials, and power stations, electric dampers are used as gas medium flow regulating or cutting devices in dusty cold or hot air gas pipelines.

Installation and maintenance

Installation:

Before installing the electric air valve, the pipeline should be cleaned and purged to ensure that there are no impurities inside the pipeline.

Check whether the model and parameters of the electric air valve meet the on-site installation requirements and technical requirements.

Install in the direction indicated by the arrow on the electric air valve body (downstream installation), ensuring good sealing at the connection.

Connect the power supply and control signal lines of the electric actuator, and perform necessary debugging and testing.

maintain:

Regularly inspect the actuator, transmission mechanism, valve body and other components of the electric air valve for damage or wear, and replace them promptly if necessary.

Clean the surface and internal components of the electric damper to remove impurities such as dust and oil stains.

Regularly check whether the power and control signal wires of the electric actuator are firmly connected, and tighten them in a timely manner if they are loose.

Regularly lubricate and maintain the electric damper to extend its service life.